INTRODUCTION

The Read Multiple Holding Registers Modbus RTU function (Modbus Function Code: 3), is used to read the contents of a contiguous block of holding registers in a remote device.

In this blog post, we will be reading multiple holding registers between Arduino based PLC set as client - server >

Latest Posts

MODBUS RTU

To know more about Modbus RTU and how the library works, please visit the following blog post:

HARDWARE REQUIREMENTS

B type cable , to program the Arduino based PLC

Two twisted pair cables, for RS485.

SOFTWARE REQUIREMENTS

CONNECTIONS

Now, in order to set a Modbus RTU communication, we are going to do the following:

1. Power the PLC between 12 and 24V.

2. Wire the cables through RS-485. This is based on a twisted pair cables, on cable from A+ to A+, and the other one from B- to B-.

3. Set the red switch to the Half-Duplex: HD

.jpg?access_token=98298898-085a-4ca9-8dc0-52c3e05f6054)

MODBUS RTU MASTER READ MULTIPLE HOLDING REGISTERS

In order to set an M-Duino as a master and the other one as a slave, we will have to program both to execute each code. So, in order to program the master, open up a new file of Arduino IDE, and paste the code below:

/*

Copyright (c) 2018 Boot&Work Corp., S.L. All rights reserved

This program is free software: you can redistribute it and/or modify

it under the terms of the GNU Lesser General Public License as published by

the Free Software Foundation, either version 3 of the License, or

(at your option) any later version.

This program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

GNU Lesser General Public License for more details.

You should have received a copy of the GNU Lesser General Public License

along with this program. If not, see <http://www.gnu.org/licenses/>.

*/

#include <ModbusRTUMaster.h>

// Define the ModbusRTUMaster object, using the RS-485 or RS-232 port (depending on availability)

#if defined HAVE_RS485_HARD

#include <RS485.h>

ModbusRTUMaster master(RS485);

#elif defined HAVE_RS232_HARD

#include <RS232.h>

ModbusRTUMaster master(RS232);

#else

ModbusRTUMaster master(Serial1);

#endif

uint32_t lastSentTime = 0UL;

const uint32_t baudrate = 38400UL;

////////////////////////////////////////////////////////////////////////////////////////////////////

void setup() {

Serial.begin(9600UL);

// Start the serial port

#if defined HAVE_RS485_HARD

RS485.begin(baudrate, HALFDUPLEX, SERIAL_8E1);

#elif defined HAVE_RS232_HARD

RS232.begin(baudrate, SERIAL_8E1);

#else

Serial1.begin(baudrate, SERIAL_8E1);

#endif

// Start the modbus master object.

// It is possible to define the port rate (default: 19200)

master.begin(baudrate);

}

////////////////////////////////////////////////////////////////////////////////////////////////////

void loop() {

// Send a request every 1000ms

if (millis() - lastSentTime > 1000) {

// Send a Write Single Register request to the slave with address 31

// It writes the value of 1000 to the register starting at address 0

// IMPORTANT: all read and write functions start a Modbus transmission, but they are not

// blocking, so you can continue the program while the Modbus functions work. To check for

// available responses, call master.available() function often.

if (!master.readHoldingRegisters(31, 0, 3)) {

// Failure treatment

}

lastSentTime = millis();

}

// Check available responses often

if (master.isWaitingResponse()) {

ModbusResponse response = master.available();

if (response) {

if (response.hasError()) {

// Response failure treatment. You can use response.getErrorCode()

// to get the error code.

Serial.print("Error ");

Serial.println(response.getErrorCode());

} else {

// Get the discrete inputs values from the response

if (response.hasError()) {

// Response failure treatment. You can use response.getErrorCode()

// to get the error code.

Serial.print("Error ");

Serial.println(response.getErrorCode());

} else {

Serial.print("Holding Register values: ");

for (int i = 0; i < 3; ++i) {

Serial.print(response.getRegister(i));

Serial.print(',');

}

Serial.println();

}

}

}

}

}

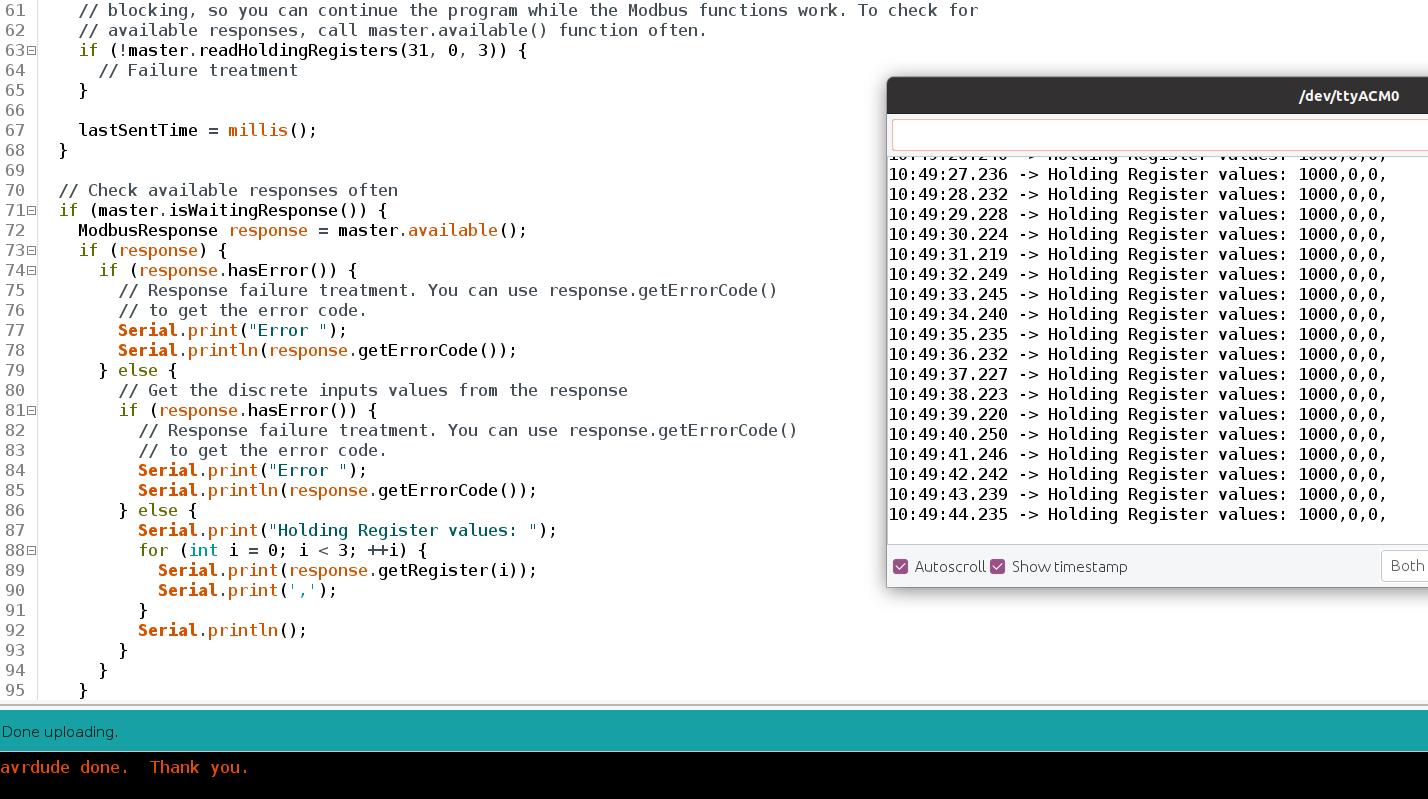

1. Once the sketch is opened, click on Tools > Board > Industrial Shields boards > And select the M-Duino family.

2. Then, select the PLC model by going to Tools > Model > And selecting the model. In our case: M-Duino 21+

3. Select the port by going to Tools > Port > And select the port of the Arduino board.

4. Finally, either click on the arrow to upload the sketch, or go to Sketch > Upload.

MODBUS RTU SLAVE

Once the master is already programmed, we are going to do the same as with the Master PLC, but choosing the ModbusRTUSlave sketch. So:

1. Change the B type cable and connect it to the other M-Duino PLC.

2. Go to the top bar, and click on: File > Examples > Tools40 > Modbus > and select the ModbusRTUSlave sketch.

3. Once the sketch is opened, click on Tools > Board > Industrial Shields boards > And select the M-Duino family.

4. Then, select the PLC model by going to Tools > Model > And selecting the model. In our case: M-Duino 21+

5. Select the port by going to Tools > Port > And select the port of the Arduino board.

6. Finally, either click on the arrow to upload the sketch, or go to Sketch > Upload.

TESTING

Before following this blog post, we set a Single Holding Register > to 1000.

Now, we can see that the value of the first holding register, is 1000: